Deep inside a GE Aviation facility, machines work around the clock printing jet engine components that would be impossible to manufacture any other way. The LEAP engine’s fuel nozzle – a part that once required welding together 20 separate pieces – now emerges as a single unit from a metal 3D printer. GE has produced over 35,000 of these printed nozzles, and they’re flying in commercial aircraft worldwide right now.

Why Aviation Embraced 3D Printing

The aerospace industry was an early and enthusiastic adopter of additive manufacturing (AM) for compelling reasons:

- Weight reduction: AM parts can be optimized for minimum weight while maintaining strength

- Part consolidation: Multiple components become single pieces, eliminating joints and fasteners

- Complex geometries: Internal channels and structures impossible with traditional machining

- Rapid prototyping: New designs tested in days rather than months

- On-demand manufacturing: Print spare parts when needed rather than maintaining inventory

The Economics of Additive Manufacturing

Traditional aerospace manufacturing generates enormous waste. Machining a titanium bracket might start with a 50-pound billet and end with a 5-pound finished part—90% of the expensive material becomes chips. Additive manufacturing builds parts layer by layer, using only the material needed. For expensive aerospace alloys like titanium and nickel superalloys, material savings alone justify the technology.

Tooling costs also favor additive manufacturing. Traditional parts require expensive fixtures, molds, and specialized cutters. AM parts need only digital files and standard machine settings. This makes low-volume production economically viable and accelerates design iteration during development.

The LEAP Fuel Nozzle Story

GE’s LEAP engine fuel nozzle has become the poster child for aviation 3D printing. The numbers tell the story:

- Traditional manufacturing: 20 separate parts welded together

- 3D printed version: Single piece, printed in metal

- Weight reduction: 25% lighter than the welded assembly

- Durability: 5 times more durable due to eliminated joints

- Production volume: 35,000+ nozzles produced and flying

The nozzle contains internal cooling passages with complex geometries that would be impossible to machine. Fuel and air mix in precisely controlled ways that improve combustion efficiency and reduce emissions. None of this would be achievable without additive manufacturing.

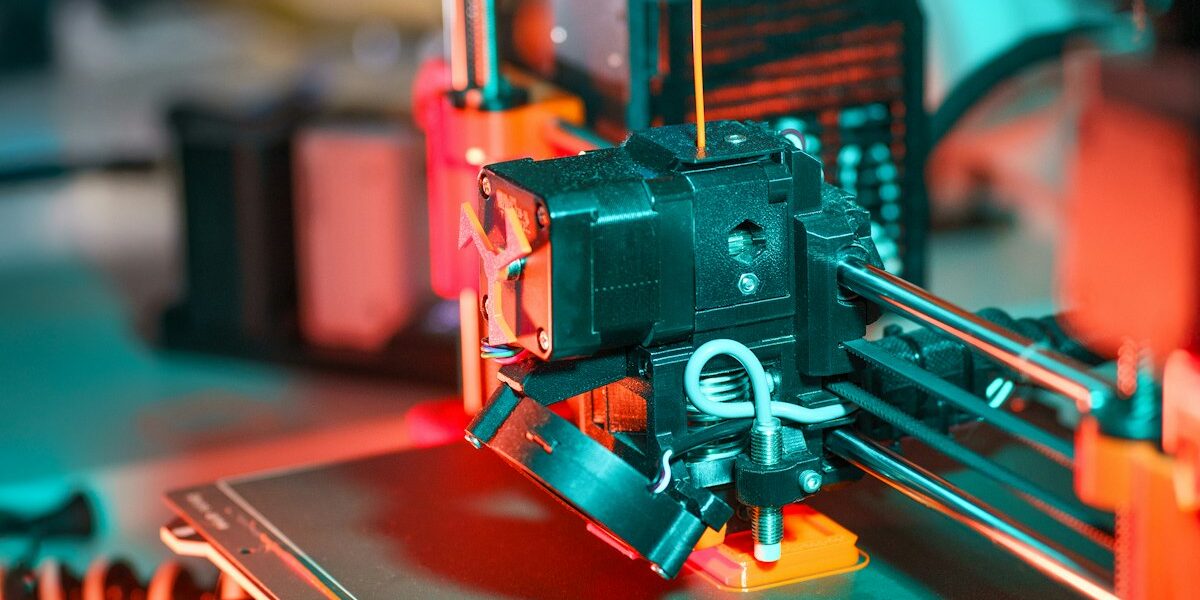

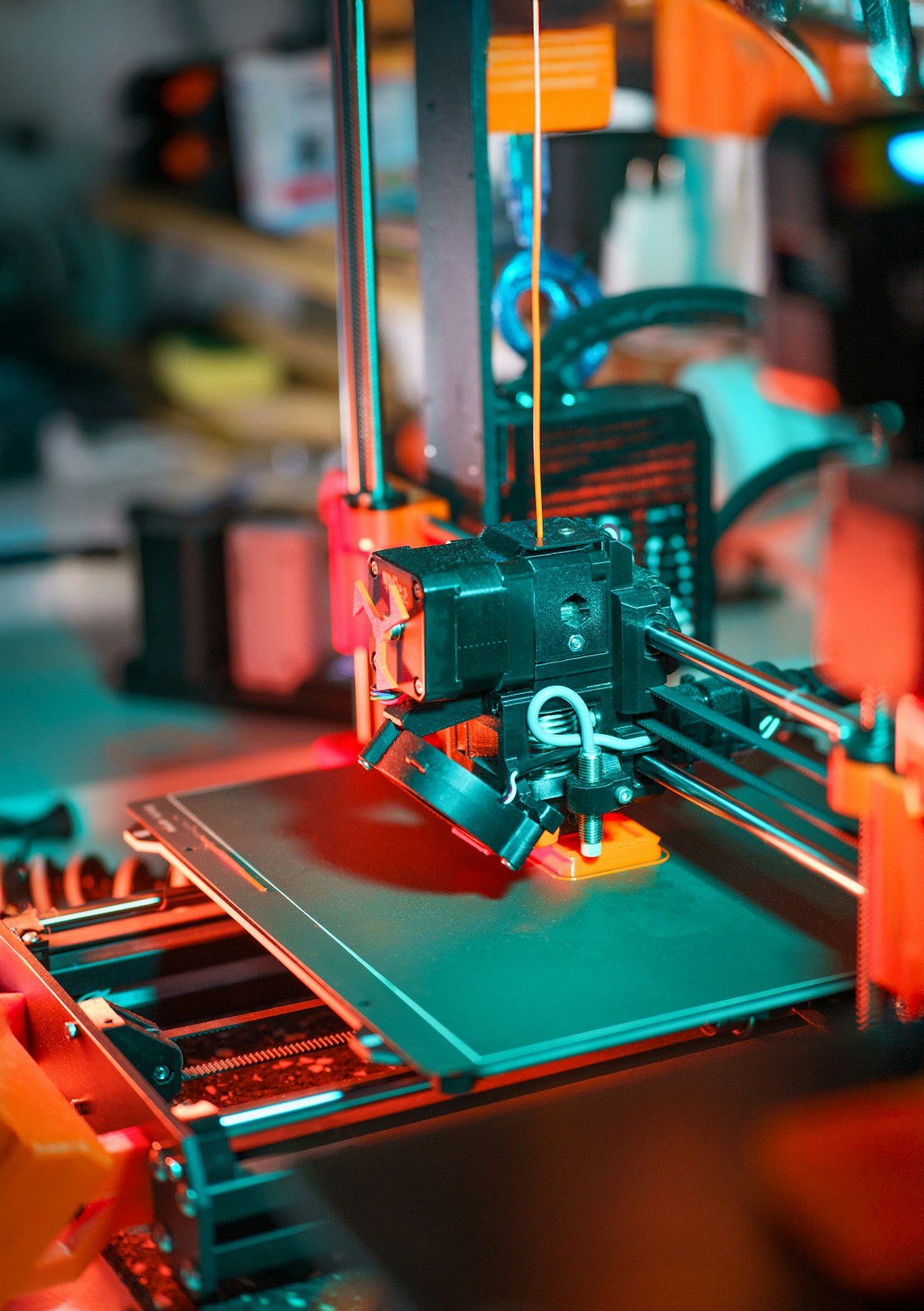

Metal Printing Technologies

Aviation uses several additive manufacturing processes, each with specific advantages:

Selective Laser Melting (SLM): A high-powered laser melts metal powder layer by layer. Excellent for complex geometries and fine details. Used for fuel nozzles, brackets, and small structural components.

Electron Beam Melting (EBM): An electron beam melts metal powder in a vacuum. Better for larger parts and titanium alloys. Used for structural components and some turbine parts.

Direct Energy Deposition (DED): Metal wire or powder is melted by a laser or electron beam as it’s deposited. Excellent for building up large structures and repairing existing parts.

Binder Jetting: A binder is deposited onto metal powder, then sintered. Faster than laser-based methods for some applications. Increasingly used for lower-stress components.

Material Advances in Aerospace AM

The materials available for aerospace additive manufacturing have expanded dramatically. Beyond traditional titanium and nickel alloys, manufacturers now print with specialized materials designed specifically for AM processes. GE developed a new cobalt-chrome alloy optimized for laser melting, offering properties impossible to achieve with conventional casting.

High-temperature superalloys remain challenging—these materials are difficult to melt and solidify without cracking—but progress continues. Successfully printing turbine blades in single-crystal superalloys would revolutionize engine manufacturing.

Beyond Fuel Nozzles

3D printing is spreading across aircraft systems:

Structural brackets: Airbus prints titanium brackets for the A350 that are 30% lighter than machined versions. Boeing uses printed titanium parts in the 787.

Turbine blades: While not yet common in production, several manufacturers are qualifying printed turbine blades that could revolutionize engine manufacturing.

Cabin components: Airlines are printing replacement parts for seat components, galley equipment, and interior trim. This eliminates long lead times for parts that are often unavailable.

Tooling and fixtures: Manufacturing tools themselves are increasingly printed, reducing the time and cost to ramp up production.

The Certification Challenge

Aviation is one of the most regulated industries in the world. Every component must be certified to rigorous standards. 3D printing introduces new certification challenges:

- Material properties: Printed metal behaves differently than wrought or cast metal

- Process control: Variations in laser power, powder quality, or build chamber atmosphere affect part quality

- Inspection: Traditional inspection methods may not catch all defects in AM parts

- Repeatability: Each print run must produce identical parts

Regulators like the FAA and EASA have developed specific guidelines for certifying AM parts. The process is rigorous, but thousands of printed parts are now flying safely.

On-Demand Spare Parts

Perhaps the most transformative application is on-demand spare parts manufacturing. Airlines currently maintain vast inventories of spare parts – some costing millions of dollars – that might never be used. With 3D printing:

- Digital part designs are stored instead of physical parts

- Parts are printed when needed, where needed

- Obsolete aircraft remain supportable as long as designs exist

- Inventory costs drop dramatically

Several airlines have already established “print farms” at major maintenance bases, capable of producing certified parts on demand.

The Billion-Dollar Impact

Industry analysts estimate that additive manufacturing will generate billions in value for the aerospace industry:

- $3 billion in weight-related fuel savings annually by 2030

- $2 billion in reduced inventory and logistics costs

- $1 billion in reduced manufacturing time and tooling

These projections assume continued expansion of AM applications and materials, both of which are progressing rapidly.

What’s Next

The future of aviation 3D printing includes larger parts (potentially entire engine casings), new materials (ceramic matrix composites, high-temperature superalloys), and faster print speeds that make AM competitive for higher-volume production.

Those 35,000 fuel nozzles are just the beginning. Within a decade, the question won’t be which aircraft parts are 3D printed – it will be which parts aren’t.